Valve Leak Detection in Industrial Oil Pumps

- Mar 22, 2023

- 5 min read

Updated: Mar 27, 2024

*As Featured on NI.com

Original Authors: Pål Jacob Nessjøen, National Oilwell Varco Norway AS

Edited by Cyth Systems

The Challenge

Reducing human exposure to hazardous environments by developing a system to perform maintenance inspections on industrial mud pumps used in oil and gas exploration.

The Solution

Deploying an embedded system with NI CompactRIO hardware and NI LabVIEW software, which can easily be retrofitted onto existing pumps, to monitor and analyze mud pump vibrations.

As an integral part of onshore and offshore drilling, mud pumps circulate drilling fluids to facilitate drilling oil and natural gas wells. Mud pumps stabilize pressure and support the well during the drilling process and drilling fluids provide friction reduction and a means to remove cuttings. We created a leak detection system for hex pumps. The hex mud pump (see Figure 1) has six pistons, six suction valves, and six discharge valves. The six pistons are driven by a rotating, asymmetric cam. We designed a patented leak detection system based on the NI CompactRIO which monitors the suction and discharge valves of the hex pump using accelerometers.

The Case for an Automated Monitoring System

Valve leaks in piston pumps are often discovered at a late stage when the leaks are so severe that they induce large discharge pressure fluctuations and create washout damages. When a severe leak is detected, we localize it manually by listening to the fluid modules while the pump is running. It is difficult to uniquely localize a leak and distinguish the difference between a suction and/or discharge valve leak. This is where the necessity of a remote system for detecting and localizing pump leaks came into play.

Top Left: Vibration Signals With No Leaks, Top Right: Vibration Signals When D3 Valve Is Leaking,

Bottom: Pipeline leak and vibration detection LabVIEW user interface.

Valve leaks often develop quickly, so manual detection gives very little time to prepare for exchanging the defective valve(s) after the leak is detected. If the leak source is uncertain, searching for the defective valve(s) can be costly and time-consuming.

Discovering the Vibration Method

During a vibration monitoring project for hex pumps, we discovered the possibility of detecting leaks using accelerometers. We recorded vibrations at different locations, both on the pump and on the discharge line, along with suction pressure, discharge pressure, and pump speeds for different pump conditions. We used a 20 kHz sampling frequency and recorded 5-second snapshots with intervals of a few minutes. On one occasion, when recording in vibration signatures in real-time we recorded a significant change during a 15-minute period. We soon realized the spot was a growing valve leak.

After the initial discovery, we performed more tests to further explore the the observed trends of recorded leak detection. The trace numbers indicate the accelerometer/valve block number. The high intervals of the dashed help curves represent the theoretical suction phases that happen when the suction valves are closed. These curves offer easy interpretation of the vibration signals and are derived from the proximity of the sensor signal (not shown). The low values of the help curves represent the theoretical closing of the discharge valves, which happens when the respective pistons retract. The leak intervals have a lag time shift relative to the theoretical intervals. This time shift is on the order of 25 ms and comes from 1) valve inertia causing delayed valve closing, and 2) fluid compressibility causing a finite piston stroke to compress and decompress the fluid.

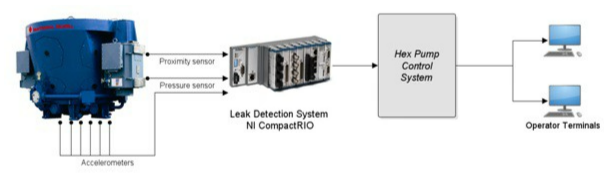

Left: Hex Pump Closeup. Right: Topology of Hex Pump Leak Detection System.

Analyzing the frequency spectra indicated that the leak induces strong, broad-banded noise from 3 kHz up to the Nyquist frequency of 12.5 kHz (half the sampling frequency of 25 kHz). The overall noise level increases by a magnitude of 30 dB.

Leak Detection System

Based on that encouraging experience, we wanted to include this condition-based maintenance system as a standard feature on all hex pumps. We developed the system as a stand-alone module to add to the existing hex pump control system (see Figure 4). Slightly simplified, it consists of the following components: accelerometers (one per valve block), a proximity sensor picking up pump speed and phase, a discharge pressure sensor, an embedded monitoring system (NI cRIO with NI 9234 acquisition modules for powering the accelerometers and acquiring high-frequency data), signal processing software and alarm logics implemented using LabVIEW software running on the cRIO monitoring system, and an HMI user interface developed in LabVIEW.

The data acquisition and signal processing is briefly described by the following steps:

Capture high-rate data (25 kHz sample rate) from all sensors during a short time interval covering at least one pump cycle.

Bandpass filter the acceleration signals to minimize the influence of ambient pump vibrations.

Analyze the timing signal to find pump speed and cam angle.

Construct adjusted window functions that selectively pick the filtered acceleration signal in every valve closing phase (adjusted here means narrowed and time lag corrected so that valve closing spikes are excluded).

Use these windows to calculate the RMS vibration level for each valve closing phase

Normalize the vibration levels through division by the median vibration level.

Set a leak alarm if one or more of the normalized vibration levels exceed a specified threshold during a certain time interval.

The default sampling frequency of the signals is 25 kHz, but the system can handle higher rates if necessary. The bandpass filter is optional, but experience shows that it improves contrast and detection sensitivity. Signal strength normalization by the median vibration level makes the detection nearly independent of the inherent ambient vibrations, which increase rapidly with increasing pump speed and discharge pressure. The last requirement, that the detected leaks last for a set time, eliminates erratic alarms caused by debris or large particles that can cause temporary seal malfunction.

We can remotely verify the leaks detected automatically by signal processing in several ways. First, the operator can view and interpret the vibration signals directly from graphs. Second, the operator can selectively listen to the recorded acceleration signals as audio signals to hear the leak sound. Third, the operator can check to see if the mean discharge pressure is stable or dropping. Lastly, the operator can see if the lowest pressure harmonics are growing.

We can use the desktop application shown in Figures 5 and 6 on a terminal to review the LDS and read raw logs and trend files directly from the LDS. This additional feature gives the operator the chance to get a closer view of the vibrations and perform audio playback to the user. Also, we can view the high-rate log of the discharge pressure to reveal a cyclic variation drop. This helps provide a better understanding of what is happening with the valves.

Conclusions

Based on the field experience of the new leak detection system, we concluded that our leak detection method offers many advantages over current practices, including the following:

High sensitivity for early leak detection and localization

Remote, continuous, and computer-based pump monitoring

Increased safety through less human exposure to hazardous environments

Multiple leak detection and localization (in hex pumps)

Reduced maintenance time and cost because leaky valve(s) are localized before the valve exchange jobs start

Easy to retrofit existing pumps because accelerometers can be attached by glue, magnets, or tape

NI’s CompactRIO hardware platform and LabVIEW software platform proved to be fast tools for prototyping our system and gave us an embedded deployment system that we can reliably retrofit to existing pumps.

Original Authors:

Pål Jacob Nessjøen, National Oilwell Varco Norway AS

Edited by Cyth Systems