Hardware-Timed Automation Accelerates Gas Meter Testing

- Aug 21, 2025

- 7 min read

Updated: Aug 26, 2025

Industrial gas meter manufacturer improved product quality and validated accuracy by incorporating NI CompactRIO into end-of-line piston prover test.

Project Summary

Industrial gas meter manufacturer automated their end-of-line piston prover testing with an NI CompactRIO solution that improved quality control processes and validated product accuracy to meet the United States’ units and measures standards.

System Features & Components

cRIO instrumentation incorporated 80+ sensor inputs/outputs for handling comprehensive flow, valve control, temperature, pressure, and humidity measurements

Custom closed-loop PID algorithm for precise piston control, integrated safety control loops, and pressure release valves for safe operation at high pressures

Positioning system achieved accurate measurements, with nanometer-level precision, using linear encoder and laser detection technologies calibrated with standard gauge blocks

Outcomes

Achieved the nanometer-levels of precision and accuracy required for fiscal gas meter calibration and validation by the National Institute of Standards and Technology (NIST) and the Office of Weights and Measurs (OWM)

Enabled continuous, automated testing through implementation of the cRIO system that simultaneously manages both the control of actuating hardware and the measurement of necessary sensors

Successfully deployed system within project timeline constraints despite equipment access limitations making remote development necessary

Technology at-a-glance

NI C Series Modules

NI LabVIEW Real-Time & LabVIEW FPGA

Modbus and Ethernet/IP industrial communication protocols

Custom PID control algorithms

Safety and Compliance in Fiscal Custody Transfer

In the natural gas industry, accuracy is not just important, it’s legally mandated. Industrial natural gas meters are fiscal custody transfer devices, the critical measurement point where customers are charged for their energy consumption, making measurement precision a requirement for protecting the interests of consumers and providers. These measurement devices must meet stringent accuracy standards set by the Office of Weights and Measures (OWM) at the National Institute of Standards and Technology (NIST). The accuracy of these meters directly impacts:

Consumer trust and fairness – ensuring customers pay only for what they actually consume

Regulatory compliance – meeting strict standards set by government agencies

Economic stability – supporting fair trade within the multi-billion dollar energy market

Safety and reliability – maintaining proper pressure and flow monitoring in gas distribution systems

Every industrial gas meter must be rigorously tested and calibrated before deployment and must also be re-certified annually to maintain accuracy. This calibration process relies on specialized piece of equipment, a natural gas prover. Provers are reference standards capable of generating known, precise volumes of gas to enable the verification of a meter’s readings.

Modernizing Legacy Equipment

A leading manufacturer of industrial natural gas meters was at an inflection point - their competitive position could change due to the age of their existing piston prover design. As an exclusively analog system, it could no longer meet the demands of modern infrastructure expansion and industrial customer needs.

They were experiencing several pain points that were becoming increasingly problematic:

Quality Control Bottlenecks: Slow, inconsistent manual testing processes created production delays and strained customer relationships. Each gas meter required extensive manual intervention during testing, making it difficult to scale production to meet growing customer demand.

Accuracy Concerns: With analog controls, achieving repeatable, precise measurements was challenging. The lack of digital precision meant potential variations in test results, which could lead to meters being incorrectly certified or requiring costly retesting.

Compliance Pressure: US Units and Measures boards maintain strict accuracy standards for fiscal measurement devices. Any uncertainty in their calibration process could result in regulatory issues, customer complaints, or even legal liability if meters proved inaccurate in the field.

Competitive Disadvantage: Other manufacturers were modernizing their testing capabilities, offering faster delivery times and more rigorous quality assurance. The company needed to modernize or risk losing market share to competitors with more advanced testing systems.

Fully-Automated Testing

The manufacturer's primary goal was transforming their analog piston prover into a state-of-the-art, automated testing system capable of handling the most demanding accuracy requirements while improving production throughput and quality consistency.

They needed a fully automated, gas meter testing solution that could achieve nanometer-level precision in control and measurement, handling over 80 different sensor inputs and outputs, all while maintaining the safety standards required for high-pressure gas testing operations. The greatest engineering challenges for their team were:

Dual-System Architecture: The modernized prover needed two separate but coordinated subsystems—one to control the mechanical operations and another for automated testing and measurement tracking. These systems had to communicate seamlessly to coordinate the entire test process.

Precision Requirements: The system needed to meet the exacting accuracy standards required by regulatory bodies, with the ability to calculate air volume versus meter readings within tolerances that would satisfy US Units and Measures board requirements.

Multi-Rate Testing: The prover had to test meters at three different flow rates, determined by precise piston head acceleration and speed control, requiring sophisticated motion control capabilities.

Understanding the Physical System

The main chamber of the piston prover was a cylindrical drum body measuring 6 feet in diameter and 20 feet in height. A piston pushed air out of the drum body and into the meter via an outflow valve and pipe system.

The piston’s movement had to be precisely controlled to calculate the exact amount of air pushed out of the body. The calibration and certification process for a natural gas meter compares the calculated air volume pushed through the system with the measurement of the gas meter to determine its accuracy. Sufficiently accurate meters are rated as ready for market deployment; inaccurate meters would undergo further calibration to ensure they would be deployment-ready.

The prover system’s repeatability and accuracy were critical, as each validated meter required annual re-certification to maintain their functional accuracy certifications.

Complex Remote Development

The gas meter manufacturer chose to enlist the help of Cyth Systems to tackle their technical challenges because of our expertise developing precision control systems and capability to develop complex automation solutions remotely.

Cyth’s engineering team selected the NI CompactRIO (cRIO) platform to fulfill the system’s control and automation requirements. A couple of key features of the cRIO influenced this decision:

Real-time performance: The programmability of the NI Linux Real-Time Operating System (RTOS) and FPGA, using LabVIEW Real-Time and LabVIEW FPGA, enabled the implementation of hardware-timed programming loops to run at 25-nanosecond intervals. These tight timing tolerances were necessary for meeting the system’s safety relay requirements.

Comprehensive I/O coverage: The system had a high channel count and a large mix of I/O and sensor types including flow, valve control, temperature, pressure and humidity sensor readings. The compatibility of the cRIO platform with NI’s C Series modules enabled the rapid and reliable integration of all the I/O required. despite the high channel count and high mix of I/O.

Cyth designed a precision control system with advanced closed-loop PID algorithms programmed in LabVIEW Real-Time and FPGA modules. The system continuously monitored piston speed and pressure feedback to enable precise acceleration and deceleration control across three different flow rates, ensuring reliable operation over thousands of measurement cycles.

Advanced motion control: Custom closed-loop PID algorithms managed piston acceleration and deceleration with continuous speed and pressure feedback adjustments throughout the testing process.

Nanometer-precision positioning: Linear encoders combined with laser detection systems and metrology standard gauge blocks ensured absolute accuracy in piston positioning for fiscal meter calibration.

Flexible multi-rate testing: System operated reliably across the full range of loads and flow rates required for comprehensive meter validation.

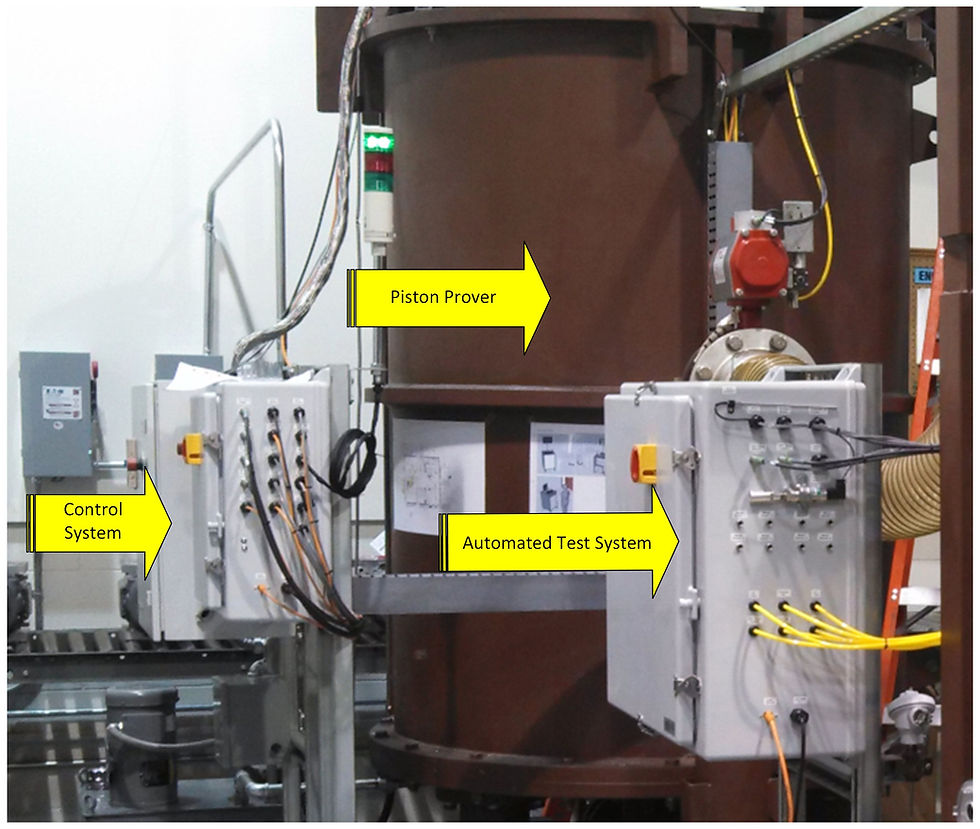

The piston prover’s two separate systems: control and automated test.

Implementing Comprehensive Safety Systems

Considering that pressure inside the prover could reach over 200 PSI, operational safety was critical for this system. Cyth's development team implemented two distinct safety loops that continuously monitored all critical parameters, including pressure levels, piston position, and system status to provide multiple, redundant protection mechanisms.

Automatic Safety Override: An independent, dedicated safety control loop was implemented to instantaneously override the system if any unsafe conditions were detected.

Emergency Stop: A comprehensive emergency stop sequence, including a pressure release valve and a hard stop for the motor driving the piston, was incorporated to enable operators to immediately halt testing in case of emergency.

Piston prover control system.

Overcoming development obstacles

The project's most significant challenge was developing and testing the prover's control systems remotely, since the massive equipment located in Texas was too large and cost-prohibitive to ship to Cyth's San Diego facility. Cyth overcame this challenge by developing hardware-in-the-loop (HIL) simulation and conducting rigorous factory testing to enable rapid deployment within the customer's two-day integration window.

Hardware-in-the-loop simulation: HIL model developed on NI cRIO-9074 enabled comprehensive testing of piston controls and sensor validation through physical transducer actuation without access to actual equipment.

Rigorous pre-deployment testing: System pre-assembly and Factory Acceptance Testing (FAT) performed in San Diego to ensure all components were verified and ready for immediate integration at the gas meter manufacturer's facility.

Rapid site deployment: Full system integration and Site Acceptance Testing (SAT) performed within the customer's maximum two-day downtime window

Operational Excellence Through Test Modernization

The comprehensive two-part control and automated testing system upgrade enabled the industrial gas meter manufacturer to successfully modernize their end-of-line testing capabilities. Their quality control processes were dramatically improved while expanding their testing capabilities and streamlining regulatory compliance processes.

Precision Achievement: The deployed system achieved the nanometer precision accuracy required by the piston prover's air delivery system, meeting all US Units and Measures board standards for fiscal custody transfer applications.

Operational Excellence: Since deployment, the system has been running consistently and reliably, helping the customer validate their industrial natural gas meters for both consumer and provider applications. The automated nature of the system has improved testing throughput while maintaining the high accuracy standards required for regulatory compliance.

Platform Advantages: The NI CompactRIO hardware platform met all high-speed communication requirements while managing over 80 sensor inputs and outputs through LabVIEW programming. The platform's modularity and programming flexibility were critical to the system's development success and ongoing maintainability.