Millisecond Control for Simulating Human Lung Behavior

- Aug 5, 2025

- 6 min read

Cyth delivers lung simulation tool to MedTech startup, bringing complex mathematical models to life on NI sbRIO with FPGA millisecond control.

Project Summary

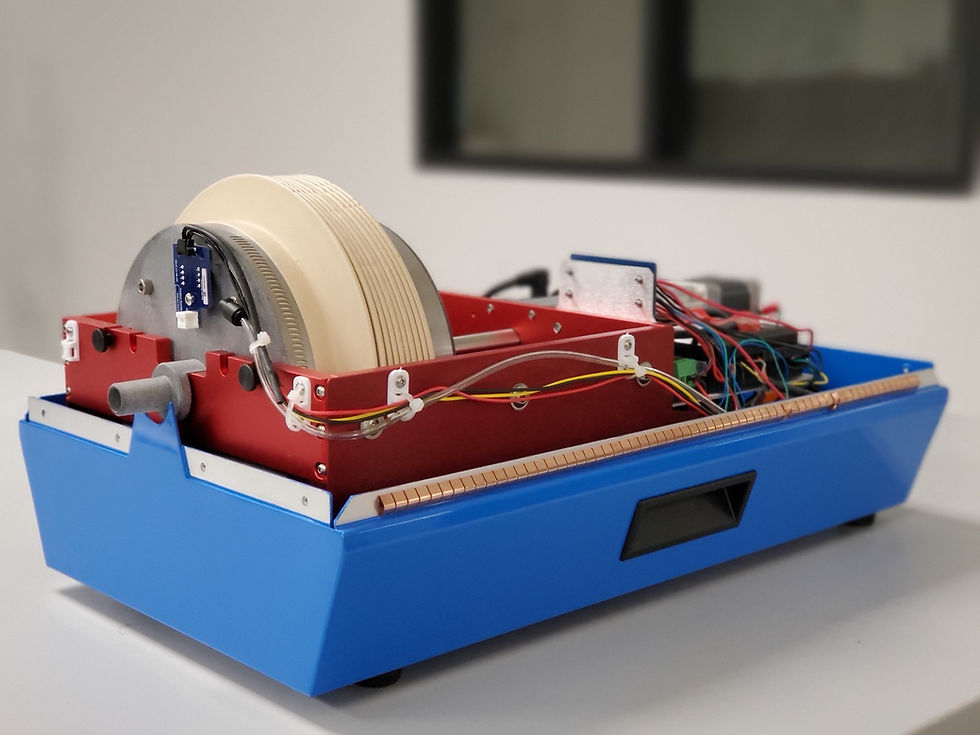

Medical technology startup developed a breakthrough lung simulator using Cyth's CircaFlex platform to achieve human-like respiratory accuracy for healthcare training, eliminating mechanical limitations of existing simulators through software-controlled parameter adjustment.

System Features & Components

Deterministic, closed-loop control to achieve microsecond-level motor control and millisecond response times for real-time simulation of lung physiology equations

Software-controlled lung simulation to enable automated operation and seamless integration with existing heart simulation device to enable comprehensive training scenarios

Linear actuator design to accurately simulate inhalation and exhalation volume exchanges with precise physiological feedback

Outcomes

Achieved human-like respiratory accuracy with nanosecond motor control and millisecond system response times

Created simulator that is expected to disrupt the market, offering continuous programmatic parameter control at lower manufacturing costs than mechanical competitors

Enabled comprehensive medical training across full spectrum of respiratory diseases and emergency scenarios through integrated cardiovascular-pulmonary system

Transitioned manufacturing to Cyth Systems

Technology at-a-glance

NI sbRIO-9651 System on Module (SOM)

Cyth CircaFlex-304 modular control board

LabVIEW Real-Time Module

LabVIEW FPGA Module

Mass Flowmeter and Controller (FMA-A2321)

SICK Displacement Measurement Sensor (OD1-B100C50I14)

SCN5 series Dyadic's Mechatronics Cylinder

Round Bellow with Cuff Ends

Revolutionizing Medical Training

Today, you will take approximately 22,000 breaths of air (Breathing, n.d.). Each one a part of the complex interplay of biological processes that many never need to think about. When it comes to medical emergencies and chronic respiratory issues, medical professionals must make split-second decisions about which life-saving interventions a patient might need.

Many times, surgeons face an uphill battle when it comes to learning how to make those decisions. Opportunities to handle unique situations and uncommon issues cannot be properly addressed in medical textbooks or by operating on a cadaver. Furthermore, surgical teams must manage extensive patient profiles filled with complex cases, ones that are nearly impossible to learn during typical training.

One medical technology startup recognized that this gap in respiratory training was putting healthcare providers and patients at risk. They set out to revolutionize how medical professionals can prepare for some of these critical moments:

Emergency Medicine Training: Preparing doctors for asthma attacks, collapsed lungs, and respiratory failure scenarios

Surgical Education: Training anesthesiologists and surgeons on ventilator management during operations

Nursing Competency: Ensuring respiratory therapists can recognize and respond to changing patient conditions

Medical Device Training: Teaching proper ventilator operation and troubleshooting across different patient scenarios

Modeling Life-like Human Physiology

Traditional lung simulators on the market were mechanical, inflexible devices that failed to adequately prepare medical professionals because they couldn't realistically replicate varying patient profiles and breathing models. The startup recognized their need for an advanced solution partner to help them improve:

Training Realism Deficiencies:

Existing lung simulators required manual adjustments to change airway resistance, meaning students couldn't experience the seamless, dynamic changes that occur in real patients.

Mechanical iris systems and solenoid-based designs created jerky, unrealistic responses that failed to replicate the smooth, continuous characteristics of human respiratory function.

Healthcare providers were lacking exposure to the full spectrum of respiratory diseases and emergency scenarios they could encounter.

Integration & Complexity Barriers:

The MedTech startup had already developed a sophisticated heart simulator, but existing lung simulators were challenging to integrate into a single system for comprehensive cardio-pulmonary medical training.

Available solutions were either prohibitively expensive for educational institutions or so mechanically complex that they required extensive maintenance and specialized technical support, limiting their practical deployment in training environments.

Designing-In Differentiation

Considering the startup's ambitious vision to create the most realistic, responsive lung simulator ever developed, the system had to execute calculations and corresponding physical responses within milliseconds to maintain realistic human breathing patterns, as any delays would immediately break training realism and compromise educational value.

Creating a life-like simulation required a system with dynamic range and continuity across the full spectrum of respiratory conditions, including:

Continuous adjustment of airway resistance, from healthy breathing to severe disease states

Dynamic changes in lung compliance based on simulated conditions like emphysema, collapsed lungs, and asthma attacks

Precise parameter control for seamless transition between emergency scenarios

Authentic physiological responses that match real patient variability

The new lung simulator needed to function both as a standalone training device and as an integrated component with the medtech startup's existing heart simulator to help ensure surgical teams have access to comprehensive training simulations that demonstrate the intricate interactions between cardiovascular and pulmonary systems during medical emergencies.

Striking a balance between advanced capability and economic viability was critically important to help encourage market adoption of the lung simulator. The final design had to be manufacturable at a cost point that would make it accessible to medical schools, hospitals, and training centers while maintaining the sophisticated performance characteristics required for effective education.

Advanced Control Architecture

The startup chose Cyth Systems because of their existing working relationship and proven expertise in solving complex real-time control challenges. Their team's expertise with precision motion control and LabVIEW programming made Cyth uniquely qualified to tackle the demanding requirements of human respiratory simulation.

The system had to execute calculations and physical responses within milliseconds to maintain specified breathing patterns, as any delays would immediately break training realism and compromise educational value.

The NI sbRIO-9651 was selected as the control platform to integrate into the final solution because it addressed the need for high-accuracy mathematical calculations alongside precise system control.

What are the key benefits of NI sbRIO-9651?:

667 MHz dual-core CPU enabled multitasking and parallel processing

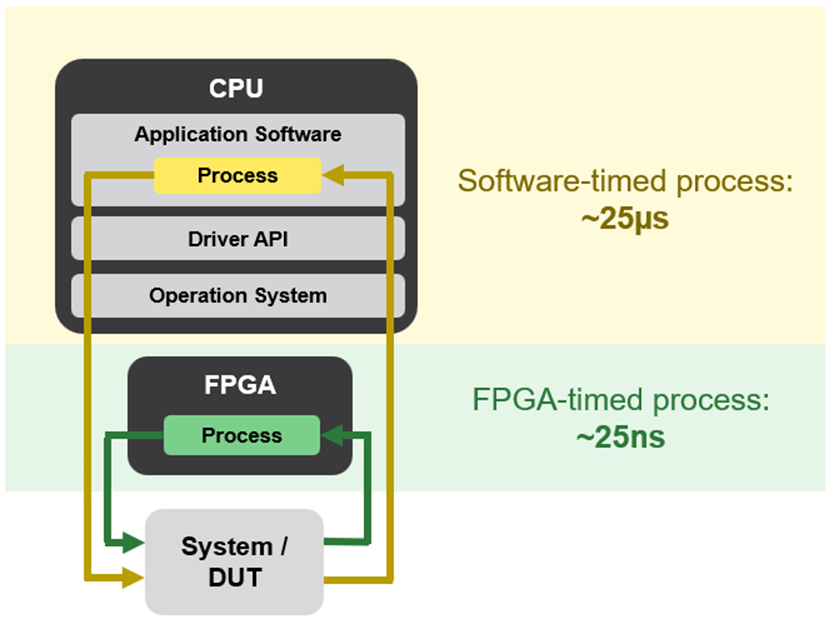

Zynq-7020 FPGA provided deterministic, real-time system performance

Compatibility with LabVIEW FPGA software streamlined FPGA programming because it abstracted away the low-level complexities of Hardware Description Languages (HDLs)

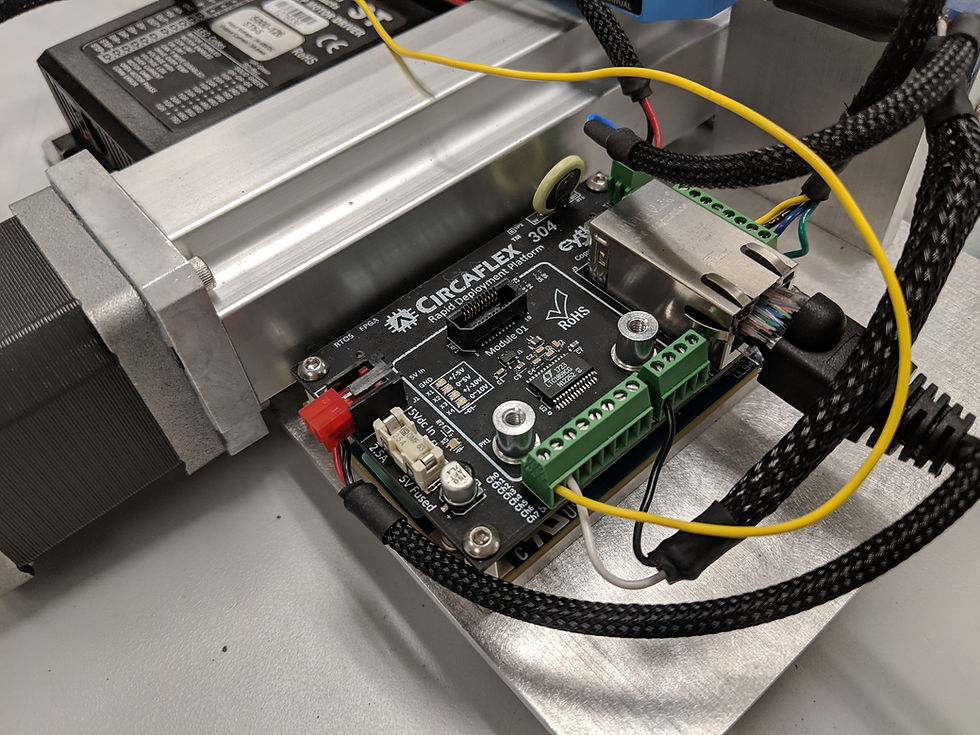

The capabilities of the NI sbRIO-9651 were further expanded by the Cyth CircaFlex-304. This COTS daughterboard for the NI sbRIO enabled:

rapid connectivity to digital TTL lines and analog voltage input channels

I/O expansion capability to enable comprehensive lung simulation control and futureproof the product

On top of this reliable hardware platform, Cyth designed a software solution that could execute the customer's complex lung function equations in real-time.

Incorporated Cyth's proprietary, field-tested real-time software architecture to ensure system reliability and maximize the processing capabilities of the CPU

Developed custom FPGA behavior to instantaneously calculate pressure and volume variables, based on the customer's mathematical equations, to control motor speed with life-like accuracy

Precision Motion for Linear Actuation: Cyth developed a linear actuator system using a precision motor paired with a rubber bellows.

Inhalation was simulated by actuating the motor expanding the volume of the bellows.

Exhalation was simulated by the motor returning to the home position, decreasing the volume of the of the bellows.

Integration of SICK displacement measurement sensor ensured all components operated within timing tolerances to continuously demonstrate critical organ interactions during medical emergencies.

Software-Controlled Variability: Cyth's solution enabled programmatic control of airway resistance and lung compliance entirely through software, eliminating the need for manual adjustments required by most lung simulation solutions

Cyth's custom software control provided smooth, continuous adjustment ranges

Mechanical wear and continuous maintenance requirements mitigated by software-enforcement of hardware operating ranges

Precision Timing Solutions: Initial testing revealed communication delays that compromised human-like responsiveness, so Cyth's engineers chose to bypass the stepper motor's control board:

Spliced directly into TTL lines for step and direction control

Replaced the RS232 communication with custom CircaFlex Stepper Drive module

Achieved nanosecond-range motor operation and one-millisecond system response delays

The NI sbRIO-based design, paired with Cyth's CircaFlex platform, enabled seamless integration with the customer's existing heart simulator. The integration of these two simulators created a comprehensive cardiopulmonary training system capable of demonstrating the critical interactions between these organ systems during medical emergencies.

Cyth's LabVIEW FPGA programming expertise, paired with their field-tested control system software architectures, allowed them to create an intuitive solution that medical educators can use to program diverse disease scenarios while maintaining the mathematical precision required for authentic training experiences.

With the integration of the lung and heart simulators into a single system at an optimized price point, the MedTech startup decided to entrust the manufacture of their products to Cyth's Manufacturing Engineering team in San Diego, California.

Economically Viable, Technically Superior

The medtech startup expects to disrupt the lung simulation market by outperforming their competitors with a solution capable of seamlessly and reliably delivering comprehensive training scenario coverage with realistic physiological responses.

The simulator's nanosecond-level motor control and millisecond response times deliver life-like respiratory dynamics to prepare healthcare providers for real-world emergencies. For the MedTech startup, the most differentiated capabilities that the NI sbRIO and Cyth CircaFlex brought to the solution were:

FPGA-enabled precision for calculating simulation parameters with continuous adjustment response times

Hardware standardization across heart and lung simulators for improving system reliability and simplifying manufacturing processes

Flexible hardware and software platforms for ensuring adaptability of system to future requirements

The MedTech startup is primed to penetrate their target market of educational institutions with a clear business case:

Technically superior simulations deliver high training effectiveness

Economically viable price point facilitates capital equipment acquisition

The MedTech startup and Cyth continue to collaborate on advancing cardiopulmonary simulation. Their goal of continuous improvement in healthcare training technology ensures that these products will remain at the forefront of medical education industry.

Citations

Breathing. Breathing | Canadian Lung Association. (n.d.). https://www.lung.ca/lung-health/lung-info/breathing